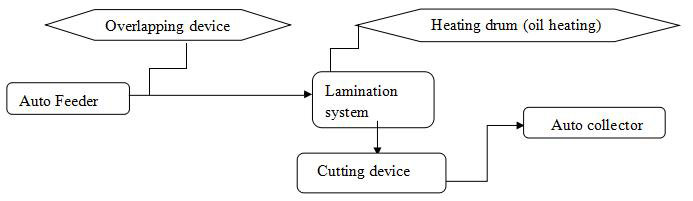

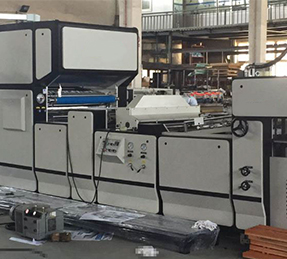

The SMW-1050D is a high speed laminating machine specially developed for high volume industrial needs where flexibility and quick turnaround is needed. This is a fully integrated system incorporating an automatic feeder, a powder cleaner, a lamination station, an automatic sheet separator and an integrated stacker which allows you to produce high quality laminated work combined with an excellent profitability factor. The SMW-1050D is an ideal solution for all your high volume lamination needs. Two large user-friendly touch screen control panels, the easy access to all vital parts of the machine allowing quick adjustments contributes to reduce considerably set up times.

The auto feeder with the pre-stacking and non-stop paper feeding function to ensure the lamination continuous and save time, so as to increase the productivity. With servo drive over overlapping system,The overlapping precision: ≤±2mm. The auto feeder with the limitation of maximum and minimum paper, and the maximum paper and minimum paper length ratio is limited in 3:1

The powder cleaning unit is dry type cleaning, combined by dust brushing absorbing and thermal pressing roller powder removing. The powder cleaning should process after the paper finished overlapping, the conveying belt and feeding system should make sure straight and stable moving during

Combined by gluing unit, drying unit and compress laminating unit. Gluing unit evenly gluing, adopt chrome-plate roller and doctor blade for gluing, gluing precision ≤ 0.008mm. The drying unit adopt big diameter thermal heating drum (diameterΦ550mm), temperature control within 80℃, heavy hot air circulating, so can achieve the fast drying purpose, at the same time can assure the film not stretch and break. The heating steel roller adopt oil heating (inner heat), diameter Φ380mm. The Rubber pressing roller hydraulic cylinder inner diameter 63mm, max pressure can reach 10ton, so can assure the high speed lamination requirement. Rubber pressing roller lift up and down with automatic control device, convenient control the pressure and more easy operation.

If the width of film is bigger than the sheet, you can use the film cutter to cut the edge. Pneumatic shaft with magnetic brake tension control The powder cleaning should process after the paper finished overlapping, the conveying belt and feeding system should make sure straight and stable moving during Also can with differential slip shaft and straight rubber roller for multi roll lamination (option)

The paper separating device adopt blade disc rotary cutting, can assure paper which above 105gsm can be effectively cut. The cutting system adopt frequency conversion speed control so can synchronously working with main lamination syste

It also equipped with chain knife flying cutting device which focus on the PET, PVC film separating The MPET materials is hardness and not easy to tear it up. After passes through the laminating cutting section, you can using this system to cut it off immediately. The finished products will deliver to stacker Automatically.

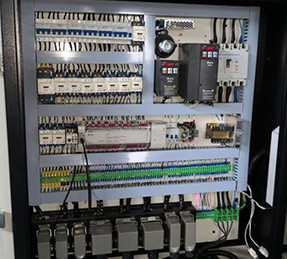

The whole lamination system with computer touch screen, simple and stable operating. Touch screen can be movable type (optional)

Some of the film roll is very heavy, operator can using the movable lifter to lift the film roll on the pneumatic shaft.

| Model | FM-1050B |

|---|---|

| Max.sheet size | 1050×1450mm |

| Min.sheet size | 360×290mm |

| Paper weight | 100-500gsm |

| Speed | -70m/min ( according to the material, printing ) |

| Total power | 69kw with powder |

| Machine dimension | 11000*2200*2400mm |

| Machine weigh | About 8800kg |

| NO. | Item | Brand | Origin |

|---|---|---|---|

| 1 | Main moto | ManLi | Zhejiang |

| 2 | Feeder | Run Zhe | Zhuji |

| 3 | Vacuum pump | Becker | China |

| 4 | Bearing | NSK | Japan |

| 5 | Fibre-optical Photo Senso | Omron | Japan |

| 6 | Relay | Schneider | Frence |

| 7 | Green flat button | Schneider | Frence |

| 8 | Red flat button | Schneider | Frence |

| 9 | Emergency button | Schneider | Frence |

| 10 | Two position K | Schneider | Frence |

| 11 | AC contactor | Schneider | Frence |

| 12 | Switching power supply | Delta | Taiwan |

| 13 | Temperature Module | Delta | Taiwan |

| 14 | PLC | Delta | Taiwan |

| 15 | Braking resistor | Delta | Taiwan |

| 16 | Air cylinder | Airtac | Shanghai |

| 17 | Magnetic valve | Airtac | Shanghai |

| 18 | Photoelectric switch | Diq | Shanghai |

| 19 | Touch screen | XianKong | SheZhen |

| 20 | Frequency inverter | Delta | TaiWan |

| 21 | Breaker | CHINT | Wenzhou |

| 22 | Digital counter | Dahua | Wenzhou |

| 23 | Over load Relay | AnDeLi | Wenzhou |

| 24 | Hydraulic pum | TianDi | Ningbo |

| 25 | Rotary conne | Yujie | QuanZhou |

| 26 | Chain | XiLin | HangZhou |

| 27 | Heater | LongHui | WenZhou |

| 28 | Heat radia | LongHui | WenZhou |

| 29 | Convey belt | Hulong | WenZhou |

| 30 | One way pneumatic diaphrag | FeiYa | WenZhou |

| 31 | Blower | YinNiu | TaiZhou |

| 32 | Oil hos | HuiLong | HuNan |

| 34 | Encoder | OMRON | Japan |

| 35 | 5 Rewind motor | Shanghe | Shangha |

| 36 | Pressure gauge | HuaYi | HangZhou |

| 37 | Optical fibre amplifie | LEUZE | Germany |

| 38 | Optical fibr | OMRON | Japan |

| 39 | Chain knif | VICOOL | ShenZhen |

| 40 | Chain knife control touch screen | WenView | TaiWan |

© Copyright 2022 Daya Printograph. All Right Reserved